Just in time for the holiday season, FIDM Museum Registrar/Coordinator Leigh Wishner shares her research on our ‘Toy Solider’ textile fragment, likely inspired by the 1934 MGM classic Babes in Toyland. Read on to learn how this dynamic textile was made – including rare photographs of the fabric in production at the mill, courtesy of the Hagley Museum and Library, Wilmington, Delaware. Grab a mug of hot cocoa and join us for a trip to ‘mystic, merry Toyland!’

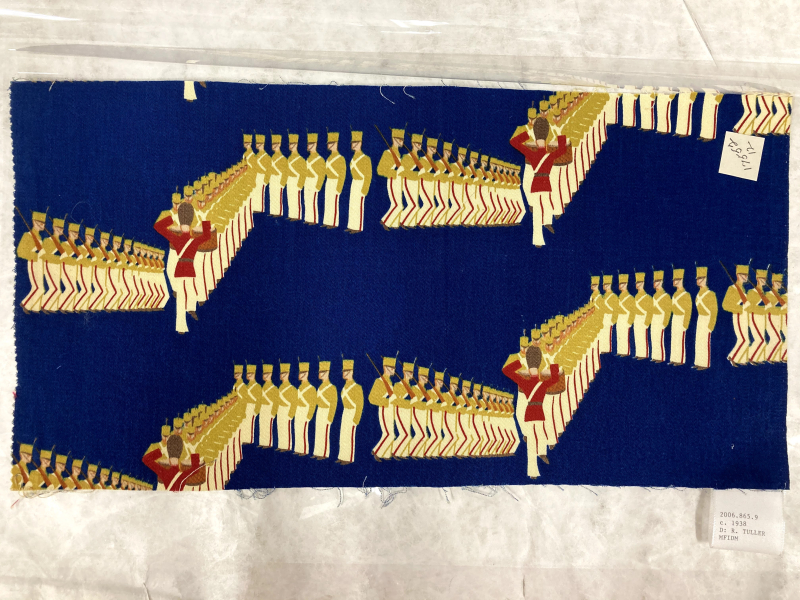

Printed Cotton Fragment (probably a furnishing fabric)

1935-1938

Gift of Roberta Tuller

2006.865.9

Have you ever wondered how a pattern is printed onto fabric? There are many methods, and textiles often provide clues that help determine which technique was used. I have a wonderful case study in textile printing to share with you, and it all started with a fragment...

It’s easy to dismiss a fragment or swatch as “just a scrap”—something most people would toss into the trash. Though museums strive to collect textiles that meet certain display criteria, such as full selvedge widths at substantial lengths, textile fragments can meaningfully supplement any collection. Sometimes a fragment’s rarity is all the justification a curator needs to add it (however minuscule) to their institution’s holdings. In other circumstances, small pieces can be valuable teaching tools in educational settings or study collection resources. A fragment may even be exhibited if it has an impactful story to tell.

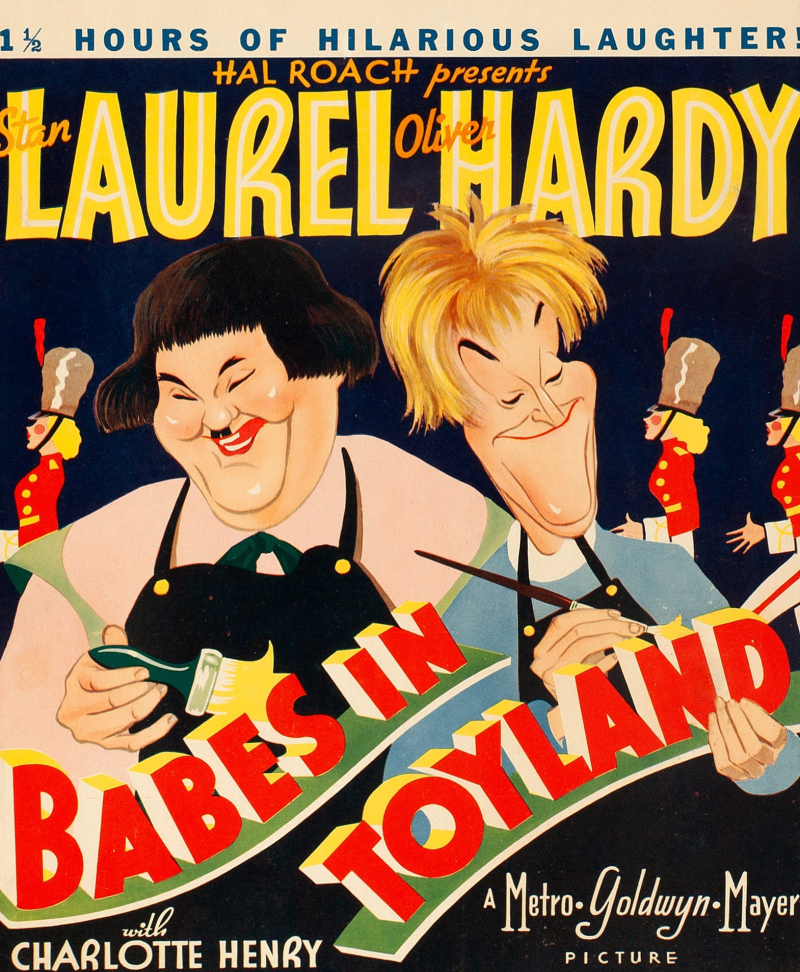

Babes in Toyland film poster (1934)

Babes in Toyland film poster (1934)

Still image from “March of the Wooden Soldiers” scene

This printed fragment is a FIDM Museum staff favorite, especially at this time of year when we shop for toys to delight the little ones in our lives. If you’ve seen the 1934 Laurel and Hardy classic film Babes in Toyland, then you must recall the memorable “March of the Wooden Soldiers” sequence (and if you haven’t seen it, you should!) This dynamic pattern features formations of soldiers aligned at sharply angled perspectives; some march with bent knees while others stand at attention. A leader, dressed in Royal Guard finery, is followed closely by columns of paired drummers and dutiful soldiers. The colors are rich yet limited to just six. Even though the uniformed soldiers look more realistic than their Hollywood counterparts, I feel there’s a compelling connection here.

Fabric’s reverse

What can we learn from observing this fragment? There is one intact selvedge, which helps determine the pattern’s direction (though, in this case, the figural motifs’ positions make the intended orientation clear). Next, from looking at the fabric’s reverse, we can tell all the colors in the pattern were printed on an off-white cloth, including the blue “ground”; sometimes, a dyed fabric will incorporate both surface printing and discharge printing (by which a bleaching agent is used to remove color from a solid-colored fabric). The uniformity of the fabric’s back confirms this fabric was never dyed blue. Finally, the size of the repeat is telling. A textile repeat is the distance at which a “pattern unit” (a full motif, whether figural or not) is replicated, ensuring an unbroken, continuous pattern. Here, the distance between the repeating diagonal bands is short, suggesting the fabric was roller printed using engraved copper cylinders—the repeat is limited by the cylinder’s diameter.

That’s what I gleaned just by spending a few quiet moments considering every detail the fabric documents. Imagine my delight when I discovered a truly informative series of archival photographs highlighting the entire manufacturing process of this very design—and confirmation of my informed hunches! The following images are from the Joseph Bancroft & Sons Co. Photograph archive (Accession 1969.025), Audiovisual Collections and Digital Initiatives Department, Hagley Museum and Library, Wilmington, Delaware. This company was active from 1831-1981; Joseph Bancroft was brought into the family textile business in the early 1820s as a partner in the Brandywine Village flannel mill operated by his father, John Bancroft Jr. For decades, Bancroft’s weaving mills, bleaching, and dyeworks plants churned out vast quantities of plain and printed fabrics. This charming design was produced at the Print Works Division in Eddystone, PA, which was acquired by Joseph Bancroft Sons & Company in 1929.

Credit line for all following photos: Joseph Bancroft & Sons Co. photographs, Audiovisual Collections and Digital Initiatives Department, Hagley Museum and Library, Wilmington, DE

Label for the Print Works Division of Joseph Bancroft & Sons Co. (Eddystone, Pa.)

Here are the “start to finish” photos, captioned with archival titles; many images have key information recorded on their versos. In some cases, I will provide information from similar photographs in the archive to highlight process details. Though no dates are recorded, plant workers’ clothing and hairstyles generally place the photos in the 1930s—and, knowing how novelty prints tend to come out at the time of (or shortly after) a mainstream cultural event such as the release of a popular movie, like ‘Babes in Toyland’, I would date this fabric to 1935-38. I particularly appreciate seeing this pattern as yard-goods, and I hope you are impressed by the number of steps (including “fixing” the print on the fabric via soaping agents) that go into textile production—most of which still apply today.

Please enjoy watching these marching soldiers leap from paper to printworks!

Sketchmaker at work at Print Works Division (Eddystone, Pa.)

Pantagraph operator at work at Print Works Division (Eddystone, Pa.)

‘The pattern being transferred to its individual color rollers is being reduced from the enlarged plate size of the design to its normal size. We have twenty-five machines. The cost of these units run from $1500.00 to $3500.00 each.’

‘The various colors are traced on individual rollers. A 10 color pattern calls for 10 copper rollers. The operator is transferring pattern to the varnished copper cylinder. The stylus point or finger of the machine is guided to follow the intaglio cut line of the zinc plate so that this motion is transferred through diminution bars and carriages to the diamond carriers that work direct to the surface of the roller scratching the part of the pattern the roller in the machine represent.’

Etching on rollers at Print Works Division (Eddystone, Pa.)

‘The acid contacts the copper surface where diamond points have scratched the given part or color that goes on the roller being handled. All work up to this point has been preliminary to this final step. The actual engraving of a copper roller is accomplished when the Etching is completed.’

Color mixing of dyestuffs at Print Works Division (Eddystone, Pa.)

‘Here various dyestuffs are mixed with the proper chemicals and incorporated into a printing paste to be applied to the cloth by means of the engraved copper roller.’

Straighteners and rollers at Print Works Division (Eddystone, Pa.)

‘Before delivery to print machine, cloth is straightened and rolled on proper size rolls which keeps pattern in proper alignment with selvage of goods.’

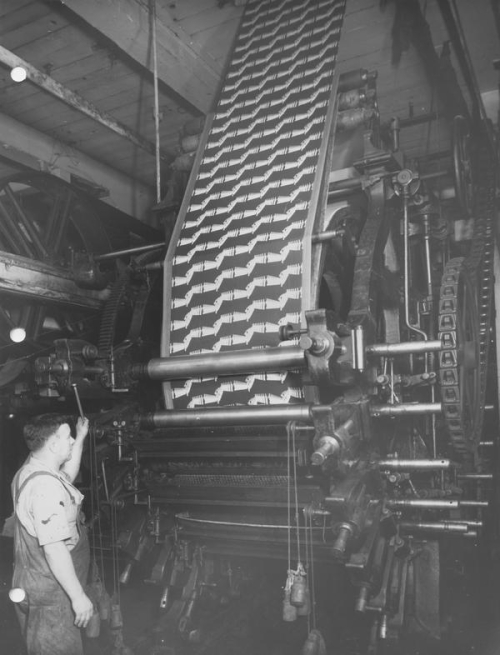

Printing textiles via engraved copper roller at Print Works Division (Eddystone, Pa.)

‘In this operation the dyestuffs in the form of a printing paste is actually applied to the cloth by means of the engraved copper roller. All colors are applied at one operation but each color is applied by a separate copper roller. This machine applies 8 different colors at one operation.’

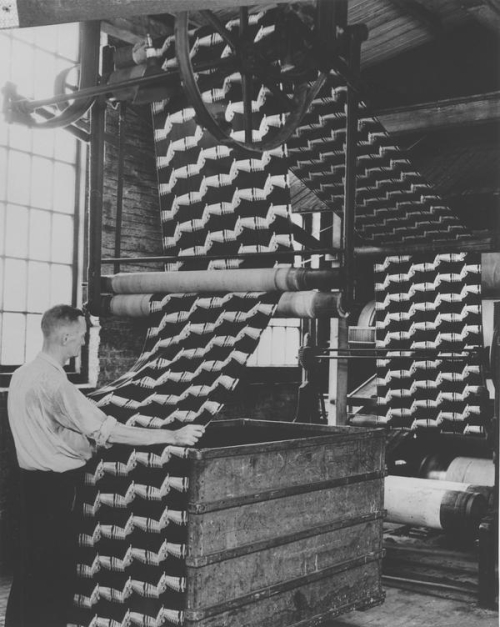

Fixing and soaping printed textiles at Print Works Division (Eddystone, Pa.)

Shrinking printed textiles at Print Works Division (Eddystone, Pa.)

‘This operation mechanically shrinks the cloth both in length and width so that garments made from material which has been sanforized do not show any appreciable shrinkage after laundering.’

Folding printed textiles at Print Works Division (Eddystone, Pa.)

‘Storage vault for storage of finished copper rollers.’